Tom Rippen hurries across the parking lot, ushered along by the winter wind off Tangier Sound that funnels down the main street of Crisfield, Maryland. He's early for his 2:30 pm meeting at The Crab Place, an Internet-direct business that ships jumbo lump crabmeat, crab cakes, and whole blue crabs caught by local watermen to far-flung customers with a taste for Maryland crab. But it's too cold not to rush, so he heads for the entrance, a door guarded by a tower of old wooden crab baskets rising towards a modern sign. The plaque advertises business at www.crabplace.com.

As Rippen enters, a blast of cold outside air mingles with the pungent, faintly sweet aroma of freshly picked crabmeat. He greets workers who are shrink-wrapping foam coolers and stacking boxes marked "RUSH — PERISHABLE."

Leaving on his brown suede coat, Rippen takes a seat in a makeshift room with a few computers located on one side of a now-defunct picking house. This is business owner Greg Cain's office, The Crab Place's base of operation. In the corner a small heater does little to warm the space.

The phone rings. Cain, who got tied up in another meeting, is still ten minutes out. Rippen nods and opens a file folder to review his notes.

When Cain first approached Rippen for advice in 2005, he was struggling with a deceptively tricky problem. He'd devised a method for chilling his crab products for up to 48 hours in transit, but the packages were bulky and required a lot of dry ice and gel packs. With his premium jumbo lump crabmeat priced at $40 per pound, he wanted to figure out how to keep shipping costs down, since they can exceed the cost of the product itself. But Cain also needs to guarantee that his crabs reach his customers in fighting form. The reputation of his company, one that caters to a growing niche market for premium Maryland crab products, depends on the quality of the product after shipping. He can't afford to miscalculate.

Rippen, a seafood technology specialist for Maryland Sea Grant Extension, has been helping him determine the safest and most cost-effective way to ship his wares long distances. For Rippen, helping a small business owner like Cain also helps the traditional Maryland industry maintain a toehold in a globalizing economy, where workforce issues and competition from overseas have put the squeeze on local watermen and processors. He's helped Cain design experiments to measure how fast the packages begin to warm using specialized data loggers. They've tested different foam cooler designs and varying quantities of dry ice. They've discussed whether it is possible for a customer who orders both fresh and frozen crab product to receive both in the same shipment. At Rippen's suggestion, Cain has even sent trial shipments with data loggers all the way to San Diego. At this meeting they'll review the outcome of Cain's trials.

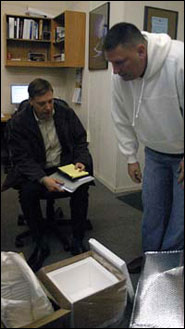

Finely temperature-controlled, but not too heavy. That's business owner Greg Cain's (top left) goal for shipments of premium crabmeat his customers order online. Maryland Sea Grant Extension specialist Tom Rippen (bottom right, with Cain) works with him to streamline his package design, helping The Crab Place, an entrepreneurial Internet-direct business, serve a growing niche market for Maryland blue crab. A worker (middle left) readies a package for afternoon shipping. Photographs by Erica Goldman.

|

Cain bursts into the office apologetically. He shakes Rippen's hand, his hulking 6-foot plus frame towering over Rippen's medium build. After exchanging greetings and chatting about some of the new directions that The Crab Place is heading, Rippen asks Cain to report on the outcome of the packaging trials. Cain brings out several examples of different package types — a six-sided foam cooler that requires assembly, what looks like silver bubble wrap, a solid-foam cooler — and begins rattling off some of his results. His trials with the data loggers showed that the single-mold foam cooler performed the best, keeping his crabs cool over the longest period of time. Adding extra dry ice brings the temperatures lower inside the cooler, but the ice evaporates in the same amount of time. This means that adding more dry ice will increase shipping costs, but not necessarily keep the package colder longer. Cain realizes that the single-mold styrofoam isn't exactly environmentally friendly packaging, but he points out that of all the package designs it's the one most likely to be reused as a beverage cooler. He plans to increase outreach efforts to encourage his customers to reuse these packages. |

|||

Overall, Cain is pleased with the results. He'd balked at moving ahead without data but now feels confident in the big investment he's recently made in packing materials. Just last week, he placed an order worth close to $100,000.

Rippen is satisfied too. He needs to check back with Cain to review the details of the data downloaded from the data loggers, but the preliminary results look good.

As Rippen leaves The Crab Place, he peers into the abandoned section of Alan Tyler's crab house next door. Its insides are gutted, windows hollowed out, beams exposed. What Crisfield has gained in businesses like The Crab Place and Linton Seafood, another Internet-direct business down the road, stands in stark contrast to what it has lost. Alan Tyler's crab house is just one of dozens shut down in small coastal communities in recent years, the casualty of workforce issues and foreign competition. And when The Crab Place moves its base of operations to a newly built facility in the coming months, the old structure will stand empty.

Rippen can't help but mourn Crisfield's losses personally. He's worked closely with the crab industry in this area since coming to Maryland Sea Grant in 1995. Much of Crisfield's transformation has happened on his watch.

But so have many of the innovative changes that have helped Maryland's crab industry remain viable. And many of these are to his direct credit (see Food Scientist Works to Sharpen Crab's Competitive Edge).

Rippen braces against the cold wind and heads for his car. As he heads out of town, he drives past the MeTompkin Bay Oyster Company, the only remaining oyster-shucking and crab-picking house in Crisfield. At the base of a conveyer belt, seagulls pick at a small oyster shell pile. Further down the street, the pavement in front of brand-new condominiums is littered with oyster shells that the gulls have dropped. A cloth sign hanging off a balcony waves, "Sleep here tonight." Rippen shakes his head. He's heard that the condos are on the market for more than $400,000. The "Seafood Capital of the World" is a changed place.

![[Maryland Sea Grant]](/GIFs/h_footer_mdsg.gif)